What is a track group?

Compared with wheeled machinery, the track group is a device that replaces tires to support equipment moving along the ground.

What does it include?

Track links and track shoes.

Download Brochure

Compared with wheeled machinery, the track group is a device that replaces tires to support equipment moving along the ground.

Track links and track shoes.

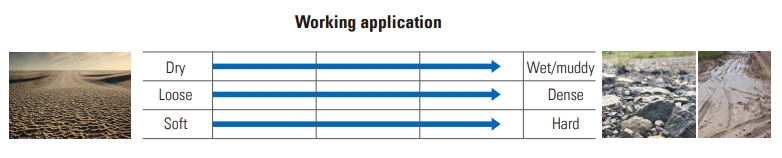

Track shoes should be selected based on ground conditions, application requirements, and the wear life of undercarriage components. As a general rule, choose the narrowest track shoe that offers sufficient flotation.

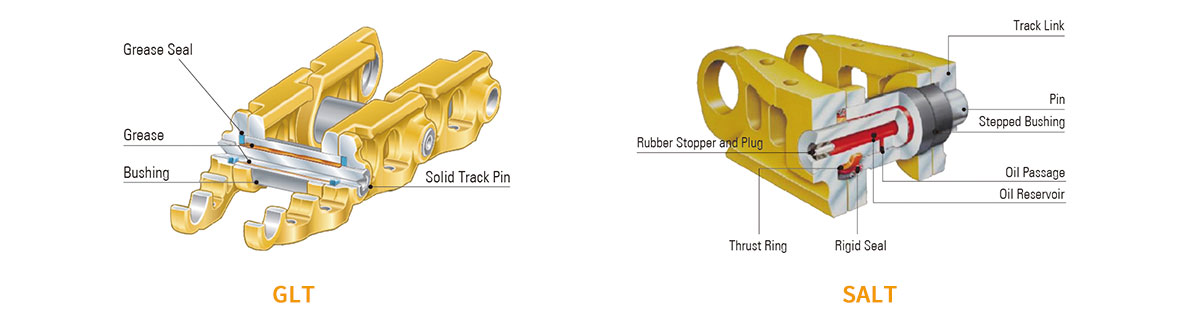

SEM offers two kinds of track links: Grease lubricating (GLT) and Oil lubricating (SALT).

Customers can combine various track shoes and links to handle complex applications. Generally, it is recommended to choose the narrowest track shoe that provides adequate buoyancy, and to select either a universal GLT link or SALT link based on specific working conditions and requirements.

Working conditions vary in severity depending on ground conditions. For example, in gravelly, muddy, or clay-like conditions, wide track shoes are recommended to prevent settling, and the SALT link is preferred for its extended service life, thereby reducing hourly costs.

How can you tell when the track will be worn out without cutting it into pieces?

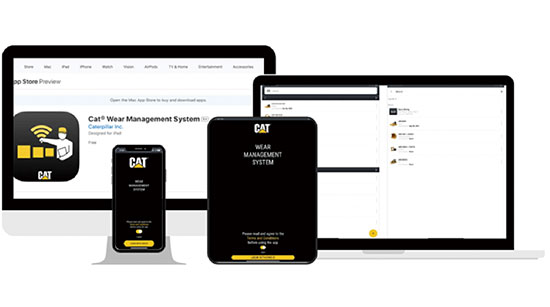

SEM customers now can use the CAT Wear Management System to measure track wear.

Simply download the CTS Pro mobile app from Google Play or the App Store and start measuring.

The CTS system is designed to help customers manage their undercarriage systems and lower costs by: